Staying ahead of your competitors in today’s rapidly evolving market is crucial to grow consistently. Once you integrate rapid prototyping into product development, it accelerates the design cycle and promotes a smooth development process. With quick prototype building, including conceptual, visual, and functional elements, your team may identify and fix design flaws immediately, which creates a more effective path to the perfect product development.

Are you wondering how prototyping accelerates the product development cycle? Check the points below:

Table of Contents

What is Prototyping?

Prototyping is the process of making a basic version of a product or idea to see how it works and to improve it before creating the final version. It’s like building a rough draft to test and fix problems early. Prototypes can be simple, like sketches or models, or more detailed, like working samples.

Example: A team designing a smartphone might create a cardboard model to test its size, shape, and button placement. This helps them make changes before spending time and money on the real product.

Top 10 Examples of Prototypes

Prototypes are like rough versions of something new we want to create. They help us see if our ideas work before making the final product. Here are 10 simple examples of prototypes:

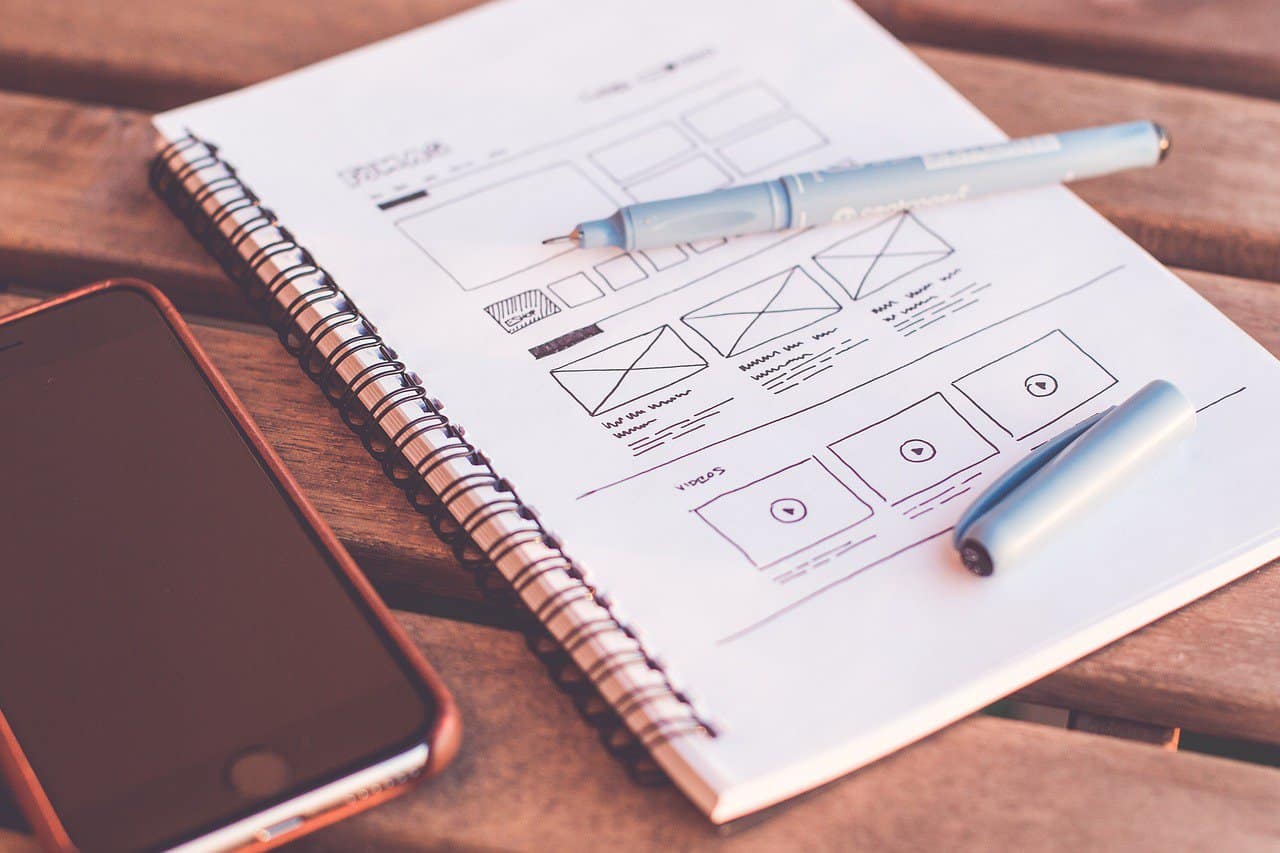

1. Paper Sketches

Imagine drawing a picture of a house you want to build. A paper sketch is a prototype to show how it might look.

2. Cardboard Models

Think of cutting up cardboard to make a toy car. This model helps you see the size and shape before making the real one.

3. LEGO Creations

Building with LEGO to try out ideas for buildings or gadgets is a fun way to make a prototype.

4. Toy Robots

Making a small robot that moves around can test how a bigger robot might work in real life.

5. App Mockups

A pretend phone screen made on paper or a computer shows how an app might work. You can test buttons and colors without coding anything.

6. Clay Models

Shaping something like a car or a doll out of clay is a good way to see if the design looks right.

7. Website Clickable Demos

Imagine a pretend website where you can click on things, but it doesn’t do everything yet. It helps to see if people understand how to use it.

8. Paper Airplanes

Folding paper into an airplane and throwing it helps test if the design can fly, just like testing real planes.

9. 3D Printed Objects

A machine makes plastic copies of things like toys or tools to see if they’re the right size and shape.

10. Video Game Demos

A simple version of a video game where you can play one level shows if the game is fun before making the whole thing.

Prototypes are like practice runs—they help us find problems and fix them before making the real thing!

9 Ways Prototyping Accelerates Your Product Development Cycle

Here are 10 ways prototyping can speed up and enhance your product development process.

1. Faster Yet More Effective Product Development

A shorter yet more effective product development cycle is one of the significant outcomes of rapid prototyping. As prototypes get produced quickly, engineers and designers can repeat and modify designs much faster, saving your time from conceptualization to marketing.

2. Validate and Test Design

Rapid prototyping helps in building functional prototypes, which almost replicate the final product. Such prototypes help in meticulous test prototype and validation, which ensures the final design fulfills all the quality and performance requirements before mass production.

3. Try Complicated Intricate and Complicated Geometries

Prototyping helps you to try out intricate and complicated geometrical designs that are sometimes difficult or impossible to make with traditional methods. It creates numerous opportunities to make creative and innovative product designs.

4. Quickly Test Many Design Iterations

The high speed of rapid prototyping helps you to test many designs, functionalities, and features in a much shorter time span to fulfill the market requirements. You can shorten the prototyping cycle from years to a few months, months to a few weeks, or days to a few hours, depending on the complications of your product. Such an agile development process ensures the final product is advanced and fulfills all the required quality standards and specifications before the final production.

5. Improve Communication and Collaboration

The advanced physical models built via rapid prototyping are effective communication tools that fill the gap between engineers, stakeholders, designers, and cross-functional teams. You can boost cross-team communication and collaboration as prototypes add tangibility to abstract concepts. The visualization and interaction with a tangible model make it easy for professionals to discuss design concepts, find potential risks, and make informed, collaborative decisions.

6. Combat Risks and Improve Decision Making

The capabilities of physically assessing and testing prototypes help in identifying and minimizing possible risks at the initial stage of the product development process. Data-centric decision-making depending on prototypes helps in making informed decisions, which reduces the chance of expensive design defects and production errors.

7. Reduce Wastage

Quick prototyping decreases the wastage of materials by correctly building objects with different layers. Besides design optimization, prototyping accelerates pre-part assessment and unparalleled efficiencies. One of the major benefits of rapid prototyping is that you can be assured of making a more worthy choice.

8. Engage More Customers and Promote Feedback

Engaging customers at the beginning of the prototyping process helps companies to collect valuable insights and feedback. The customer-oriented approach helps in developing products that meet customer requirements and expectations.

9. Fewer Development Costs and Marketing Time Than Traditional Prototyping Strategies

Prototyping is much more cost-effective than traditional techniques since it demands less labor. It saves development costs by speeding up the design process and diminishing the need for expensive tooling. The costs can always be much less as expensive molds and tooling aren’t required. Plus, prototyping reduces post-processing and time-to-part efforts. The capability of quickly building prototypes saves the time it takes to launch a product in the marketplace, which gives a competitive edge to your company.

In a Nutshell

Prototyping accelerates the product development cycle in the ways above. Rapid prototyping is significant because it revolutionizes the way products are conceptualized, manufactured, and launched. The quick prototyping hinges on high speed with which you can upgrade from a primary idea to a tangible product, which largely improves design flexibility, promotes collaboration across team members and quickly integrates feedback at all stages.

Such an approach ensures that everyone who gets involved, including stakeholders, engineers, and designers, is on the same page from the primary conceptualization of CMF (Color, Material, and Finish) prototypes and in all ways via functional prototypes. Prototyping accelerates the product development cycle, refining and making a product perfect before it gets launched.